An introduction to manufacturers of silicone rubber products:

- Making products out of silicone rubber, such as seals, gaskets, and other components is known as silicone product manufacturing. Although the production procedures and materials utilized to create silicone products differ from one product to another, each one is always of a high caliber.

- Manufacturers of silicone goods in the USA have expertise in producing silicone products and other related materials and procedures. They have extensive knowledge of design, quality assurance, and manufacturing processes. A company that manufactures silicone goods for many sectors is known as a silicone rubber products manufacturers. Their silicone goods are produced using various techniques and materials, including extrusion, injection moulding, and liquid silicone rubber (LSR). Manufacturers of silicone goods have the knowledge and experience necessary to design items specifically for their clients.

- Working with a producer of silicone materials has several advantages. They can assist you in producing items that are affordable, dependable, and long-lasting. They can assist you in creating items that are precisely catered to your demands because they have access to the most recent technology and materials.

Products made of silicone can be produced in a variety of methods. Here are three strategies:

- Compression Molding:

Compression molding is a process that entails combining a two-part silicone compound and pouring it into a mould. After that, the mould is sealed and heated to cure the silicone. Simple, one-piece objects with regular wall thickness are frequently created using this technique.

- Injection Molding:

A silicone compound is heated and mechanically injected into a mould with this technique. Tight tolerance complicated goods are frequently made using this technique.

- Liquid Injection Molding (LIM):

Using a high-viscosity silicone compound injected into a cooled mould, liquid injection moulding (LIM) is a technique comparable to injection moulding. Products with delicate detailing and thin walls are frequently created using this technique.

What factors must be taken into account while creating silicone rubber products?

Some important factors need to be taken into account while creating silicone goods. The product’s dimensions, form, function, and intended purpose must all be considered first. The material’s attributes, such as its flexibility and resilience to changes in temperature, must also be taken into account. The price of the item and any production limitations should be your last points of consideration.

What is silicone, and what advantages does it have?

Due to its strength and flexibility, silicone, a synthetic substance created from silicon and oxygen, is preferred for many items. It is an excellent material to use for creating items that can survive tough conditions because it is also resistant to extreme temperatures, UV radiation, and chemicals. The low heat conductivity of silicone makes it a perfect material for insulation. Lastly, silicone is a harmless and secure material for food-grade items.

What various silicone goods are there?

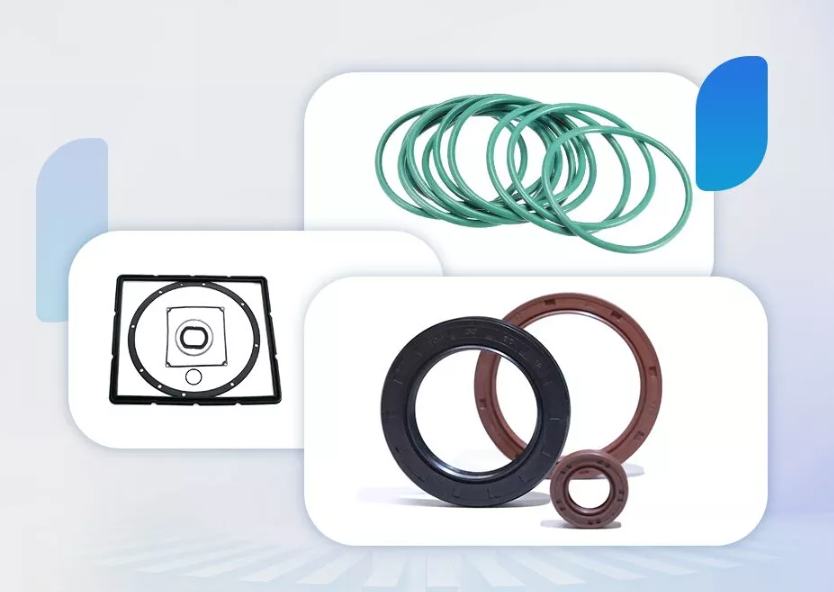

Several industries employ silicone goods, including the automotive, medical, food, and industrial sectors. Seals, gaskets, tubing, and wafers are examples of typical silicone goods. Cookware, medical gadgets, and electrical components can also be made with silicone.

The merits of collaborating with a producer of silicone rubber items:

- Working with a producer of silicone goods can provide you access to some of the greatest materials and technology available. The skilled workers at a silicone goods manufacturer can assist you in developing the precise product you want because silicone is a flexible material that can be utilized in a range of applications.

- Working with a manufacturer of silicone goods can help you save time and money in addition to giving you access to the newest materials and technology. Your items may reach the market more rapidly if you use their quick and effective design and manufacturing assistance.

- Working with a silicone product manufacturer can also help you guarantee the best possible quality for your items. They have the competence and knowledge required to produce goods that precisely match your requirements while being reasonably priced.

How to pick the best manufacturer of silicone goods for your requirements:

It’s crucial to take into account a few variables while picking silicone rubber products manufacturers. To begin with, you should confirm that the manufacturer has the knowledge and skills necessary to produce the precise item you want. Also, confirming that the manufacturer has access to cutting-edge resources and innovations is critical.

The expense of dealing with a producer of silicone goods is something else to take into account. By comparing costs, verify that you are receiving the most value for your money. Last but not least, confirm that the manufacturer has a track record of producing high-quality goods.

Quality control while dealing with a producer of silicone rubber products:

Making ensuring the items you acquire from a producer of silicone goods are of the highest caliber is essential. The producer must have a track record of creating items of the highest caliber that precisely match your requirements.

Also, confirming that the manufacturer adheres to tight quality control processes is crucial. This entails checking the items for flaws and making sure they adhere to all applicable standards and laws.

Conclusion:

From design to quality control, silicone rubber products manufacturers in the USA have experience in all facets of silicone product production. BRT provide competitive prices and manufactures goods of the finest caliber. Also, they abide by all applicable laws and requirements. Partnering with these producers can offer a practical and economical means of producing silicone goods. The process of creating silicone items is intricate and needs to be well thought out. The types of goods, production processes, mould types, raw materials, and quality control procedures must all be taken into account while producing silicone products. Your silicone goods may be guaranteed to adhere to the requirements set by your business with the appropriate information and a dependable manufacturer.