- Consistency: LSR is mixed in a machine, which helps to ensure consistency in the final product.

- Complex geometries: LSR can be used to create complex geometries and intricate designs that would be difficult or impossible to create using traditional molding methods.

- Automation: LSR is often used in automated manufacturing processes, which can help to increase efficiency and reduce costs.

- Biocompatibility: LSR is often used in medical and food contact applications, because it is biocompatible and can be formulated to meet FDA and USP class VI standards.

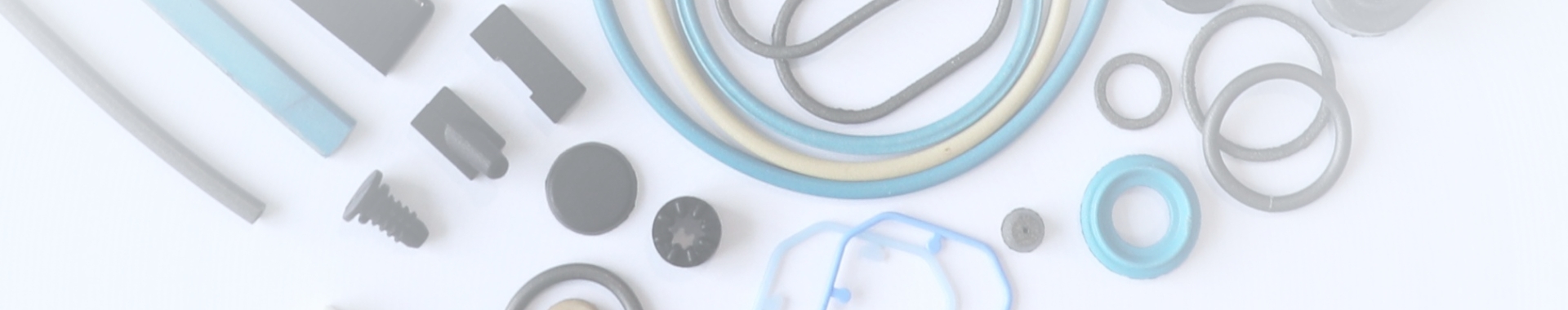

Liquid Silicone Rubber (LSR) is a type of silicone rubber that is supplied in a liquid form, rather than as a solid. It is a two-part material that is mixed together before it is poured or injected into a mold. The mixture is then cured to form a solid, flexible rubber part.

LSR has many of the same properties as solid silicone rubber, including excellent heat resistance, chemical resistance, and flexibility. But LSR has some additional advantages as well, such as:

-

BRT-12

Liquid Silicone Rubber Dongguan Bright Rubber

The hardware skeleton can be formed in one piece

lf you have any needs, you can contact us at any time, or go to the help center to check